HDPE Pipe Weld Testing

Blueline Testing have full capability to perform detailed weld analysis on all types of HDPE pipe welds including electrofusion joints and assemblies such as couplers and saddles as well as butt fusion joints. All of our HDPE pipe weld testing procedures are fully accredited with INAB and are carried out in full compliance with the requirements of Irish Water & Bord Gáis.

Booking a HDPE Weld Test.

Step One

A pipe weld sample is selected on site usually in conjunction with the clients engineer. Sample sizes should comply with the following requirements:

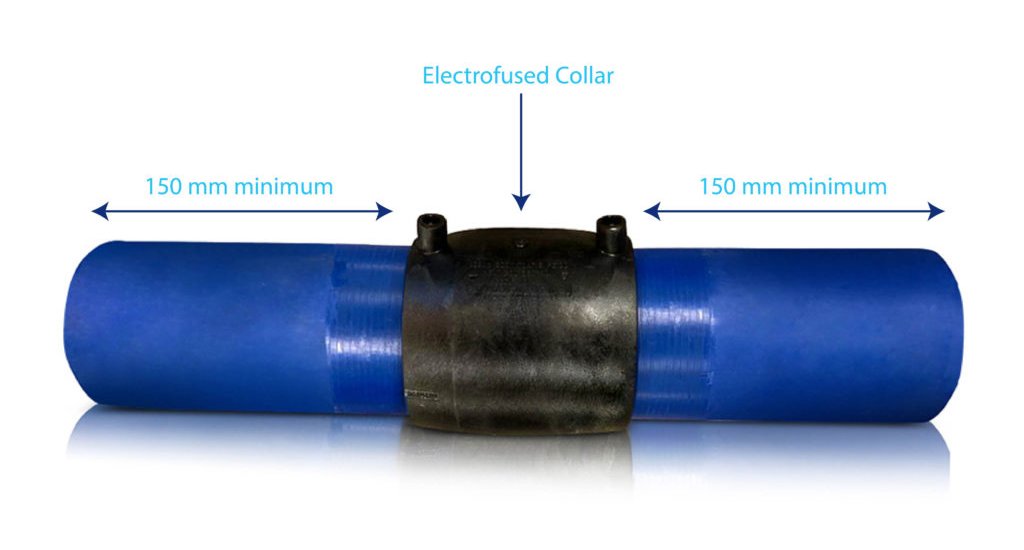

Electrofusion Collar

Minimum of 150mm of piping should protrude either side of the edge of the coupler.

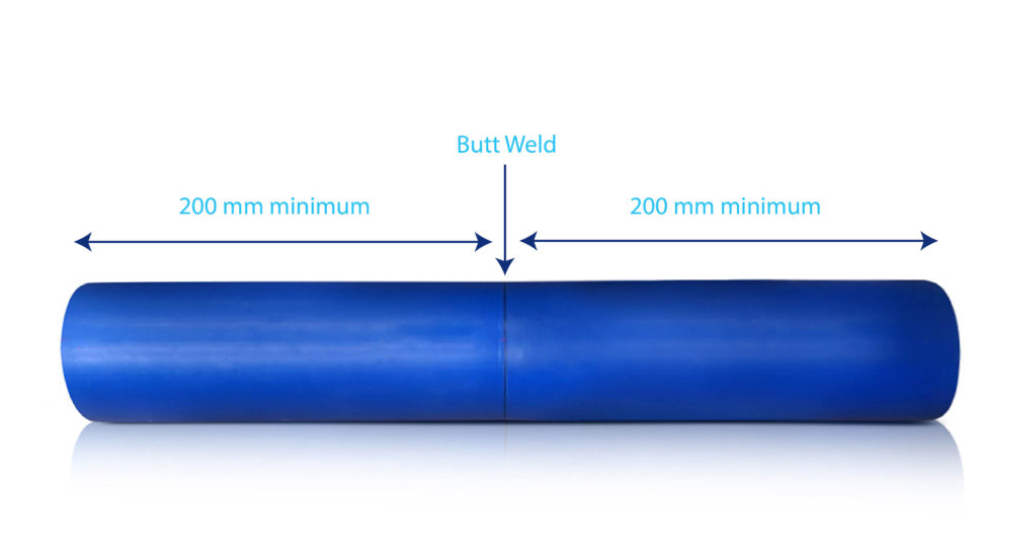

Butt Fusion Weld

Minimum of 200mm of piping either side of the butt weld

Step Two

All project and weld details associated with the sample are recorded by Blueline Testing. The pipe weld sample is prepared by Blueline Testing in our machine workshop into individual test specimens and the specimens then prepared in our conditioning facility in accordance with the associated test standard.

Step Three

The weld test specimens undergo the required test in our laboratory in accordance with the clients specifications which is typically a destructive weld test in accordance with WIS 4-32-08 as outlined in the Irish Water Code of Practice. Upon completion of the weld test a full visual & analytical fracture analysis is carried out on all test specimens. All test results are compiled in a professional accredited report and issued to the client via email.

Request a Quote

To request a quote or make a booking for this service please give us a call or send us an email.